LAMINATE TUBES

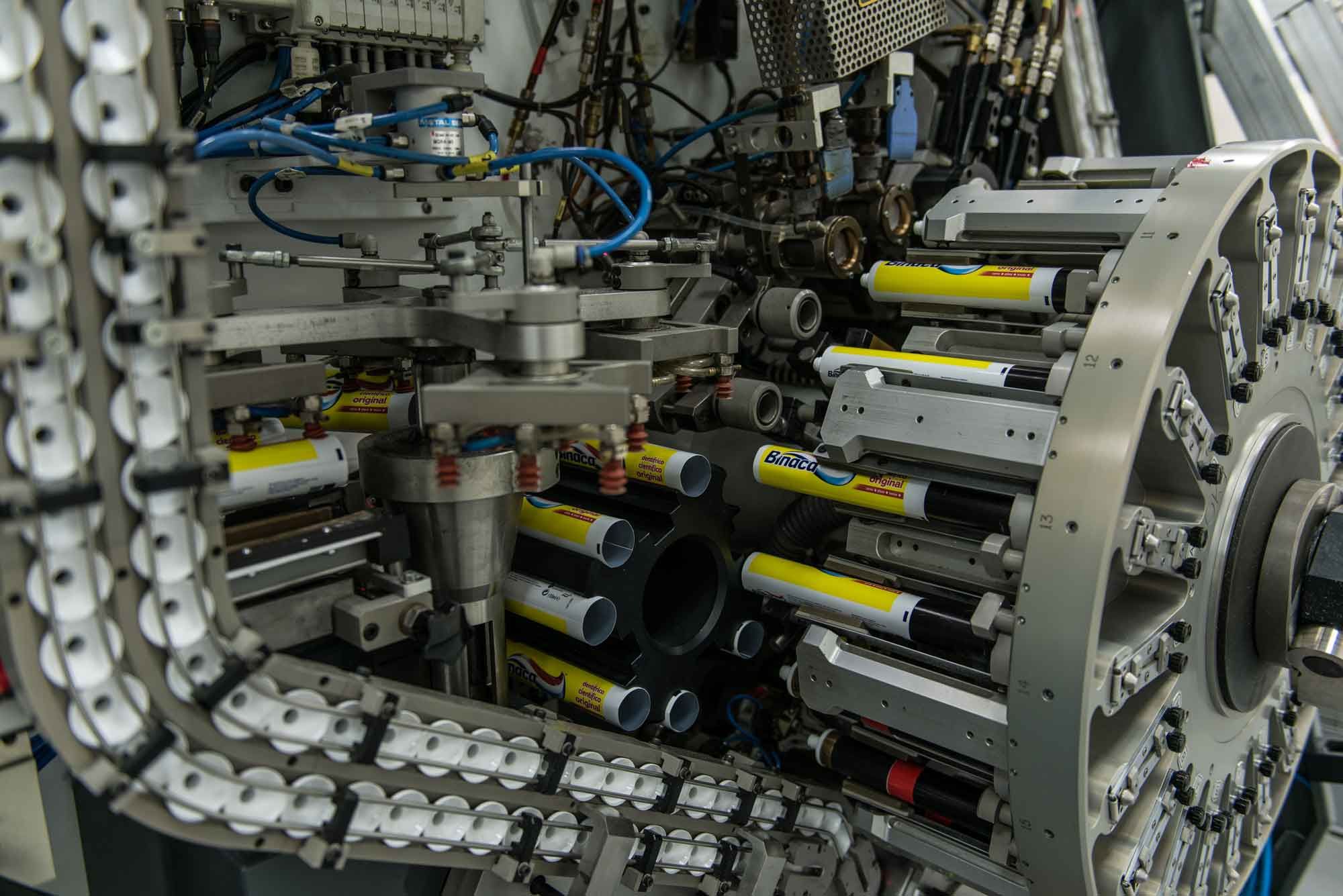

LAMINATE TUBES combine the advantages of both aluminium tubes (barrier properties) and polyethene tubes (exclusive design) thanks to the latest production technology. These tubes offer a universal solution for the packaging of toothpaste, pharmaceutical creams, food products as well as technical mixtures. The “next generation” of laminate tubes which are characterised by a highly aesthetic minimum weld, top quality decorations and oriented caps are also highly established as the optimal packaging solution within the brand-name cosmetics sector.

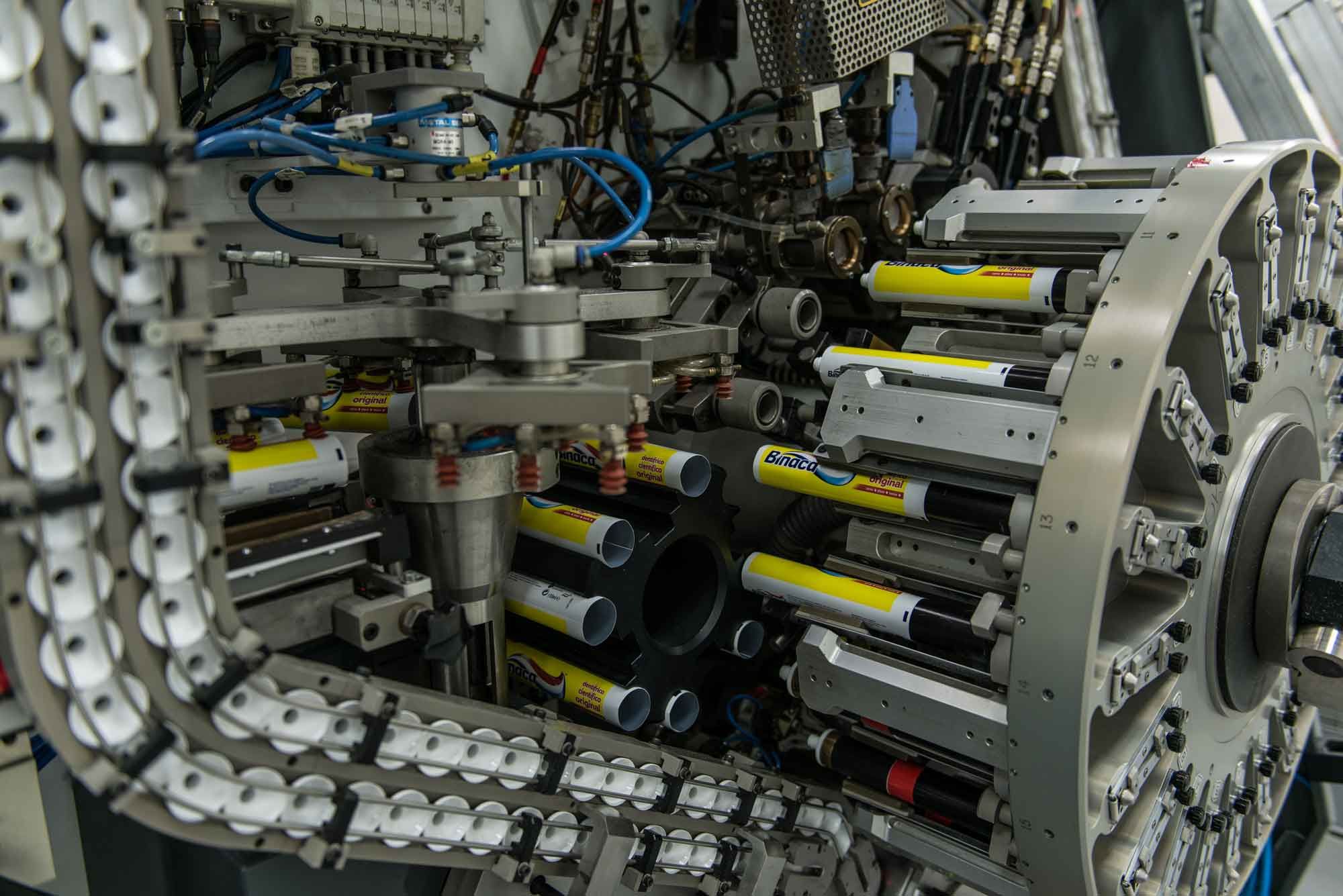

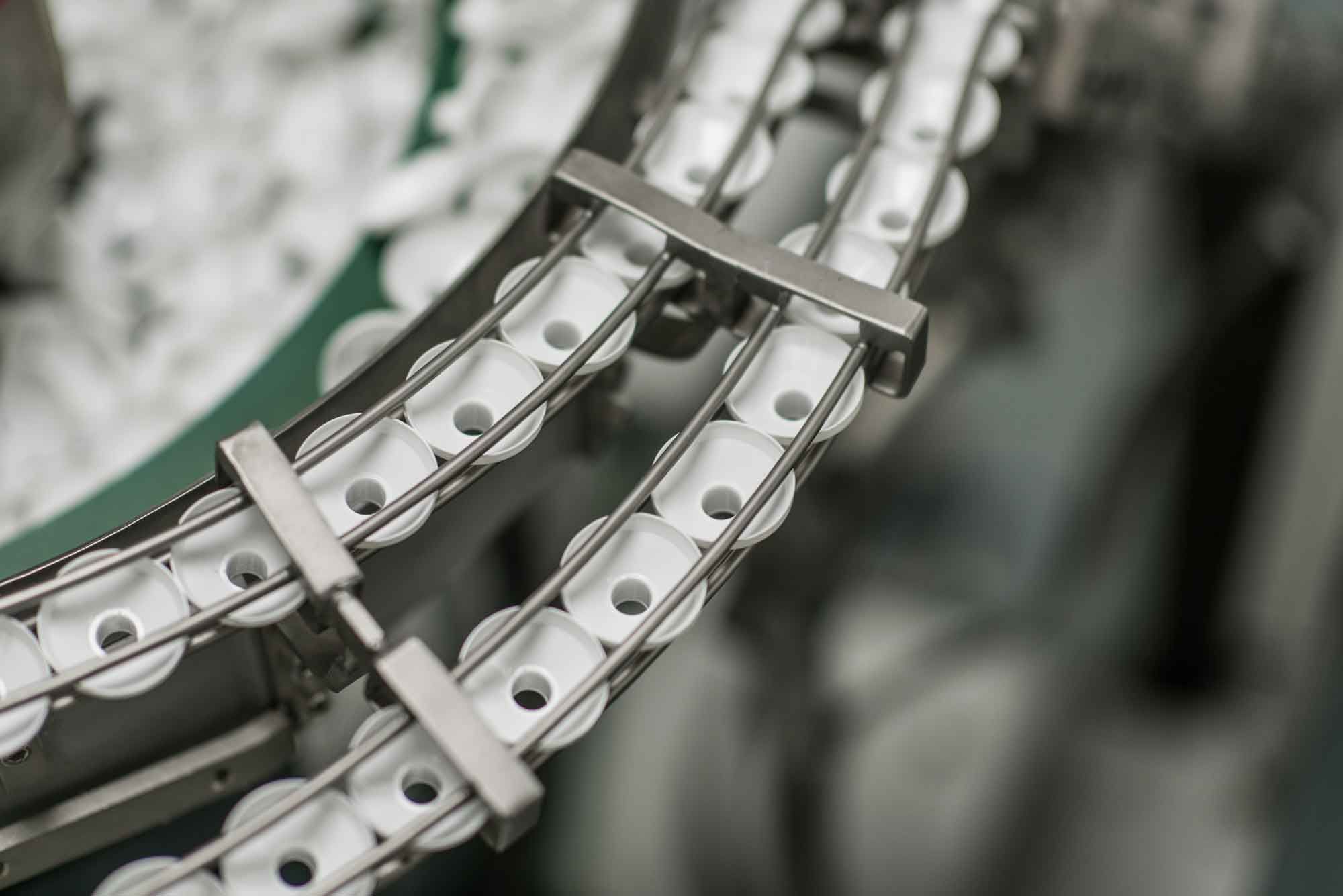

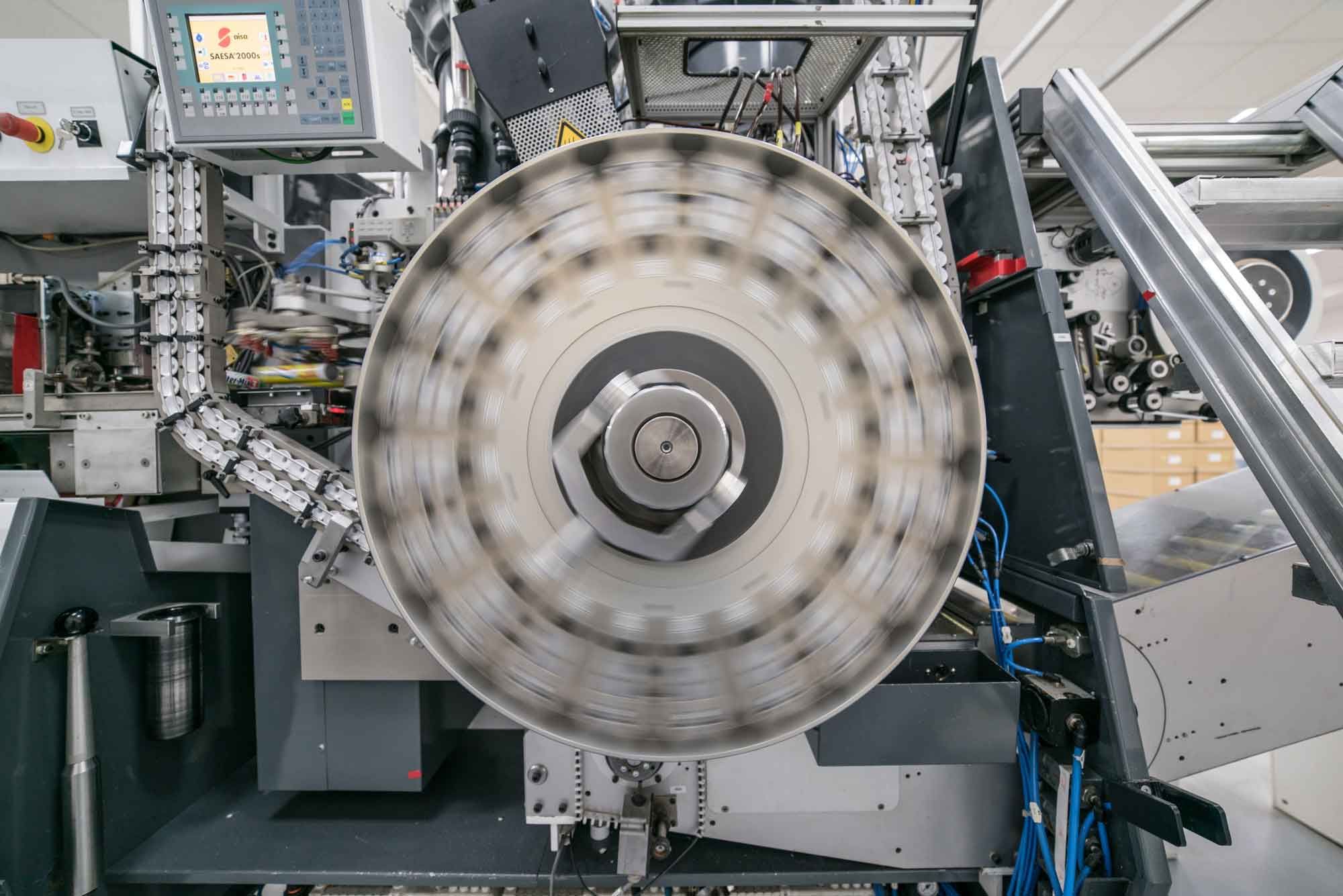

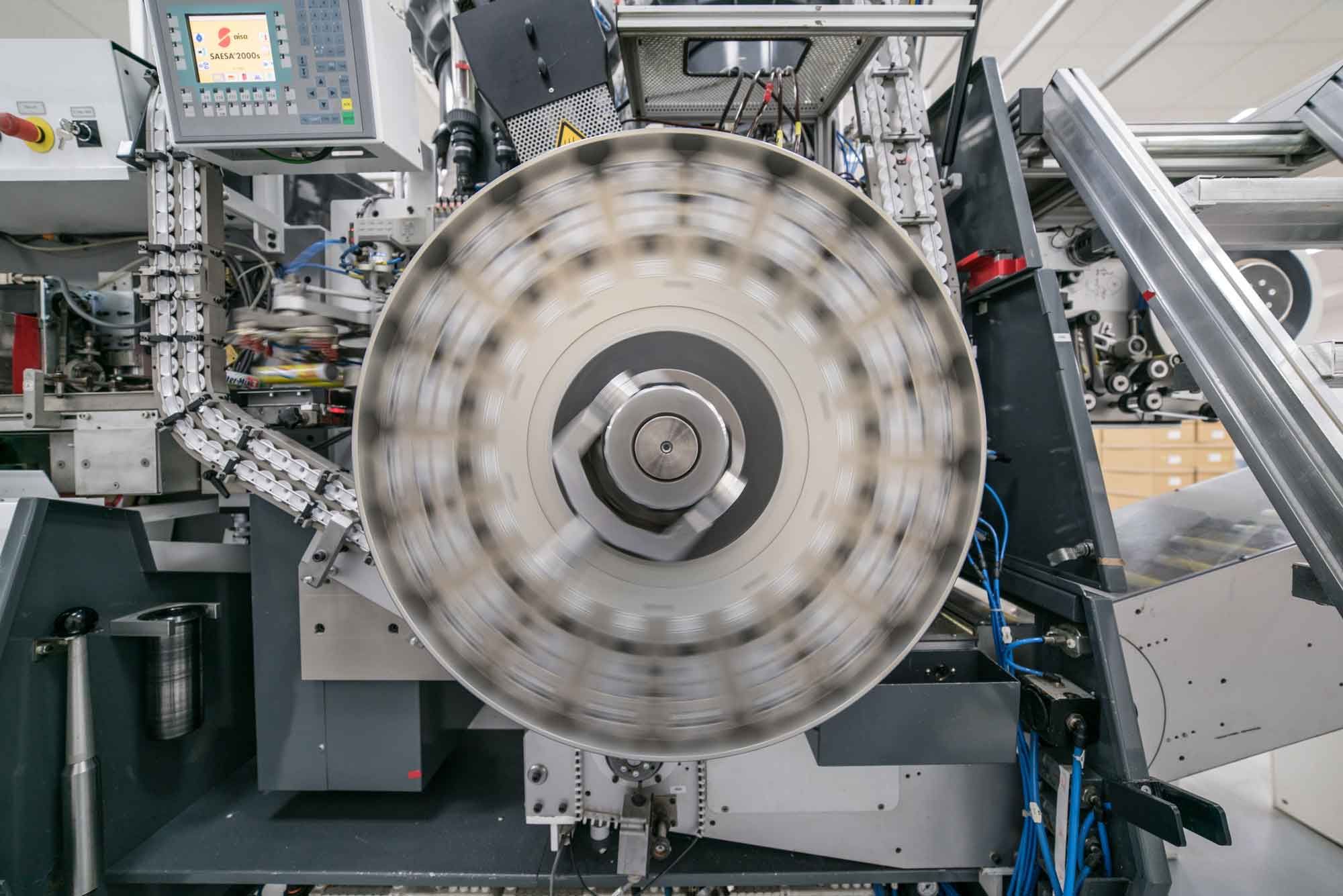

We produce laminate tubes from ABL (Aluminium Barrier Laminate) and PBL (Plastic Barrier Laminate) materials with a volume ranging from 5 ml to 300 ml. During production, we use state-of-the-art production technology including 4 Swiss AISA machines for the production of tubes and printing machine Gallus RCS 430 (flexo), for the laminate printing.

All the processes take place “in house” giving us flexibility and personalised solutions according to the customer’s needs. We also operate our own graphics studio, produce the printing plates and components and have our own company tool shop.

TUBE DIAMETERS:

19 mm

22 mm

25 mm

28 mm

30 mm

32 mm

35 mm

40 mm

50 mm

TUBE VOLUMES:

5 ml

up to 300 ml

MATERIALS:

ABL laminate web

with Aluminium Barrier in two variants - white or silver

PBL laminate web

(Plastic Barrier Laminate) with plastic EVOH barrier – variety of white, transparent or semitransparent

ENDLESS POSSIBILITIES:

variety of components

(threads and caps) – personalised solutions

variety of membranes and customer protection/originality

variety of decoration options – flexo, digital print and silk screen.